Fuel Injector Calibration

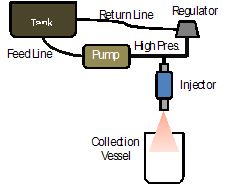

One of the first steps in tuning a fuel injection is calibrating the fuel injector. The fuel injector should be connected to the fuel rail, pump and regulator as it will be in the vehicle. The diagram below shows a typical single cylinder fueling system with gravity feed from the fuel tank to the pump, the high pressure line from the pump to the injector and regulator, and a return line from the regulator to the tank. Different regulators will have different pressures, so be sure to use the correct one for your application. Typical automotive systems will have a pressure around 3.5 bar (350kPa, or around 50 psi). The injector should spray into a collection vessel, either a graduated cylinder for measuring the volume, or a test tube for weighing the fuel.

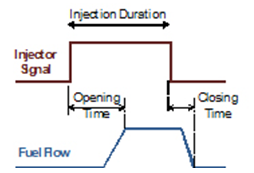

The injector does not open instantaneously. When the injector signal is turned “on” the coil in the injector applies a force opening the injection valve. It takes some time, typically 0.5 to 3.5 ms, to open the injector. During this “injector opening time” very little fuel is delivered. Once the injector if fully open fuel is delivered at a constant rate. Similarly when the injection signal is turned “off” the injector does not close instantly, and some fuel is delivered after the injection signal is shut off.

The injector opening time and the open-injector fuel flow rate are the 2 important factors to measure. To measure the open injector flow rate power up the pump and open the injector for several seconds. Make sure the injector does not over heat (low impedance injectors having a resistance of less than 5 ohms may get hot quite quickly, and can even be damaged by keeping them on too long). Measure the amount of fuel delivered and the time the injector was held open. The fuel flow rate can be calculated from the weight delivered divided by the time, ie. 25 grams of fuel delivered in 10 seconds means you have a 25/10 = 2.5 grams per second fuel flow rate. If you measured volume of the fuel you need to divide by the density of fuel, normally around 0.72 grams/cc, ie. 20cc of fuel in 10 seconds would give you 20 x 0.72 or 14.4 grams for a flow rate of 1.44 grams per second.

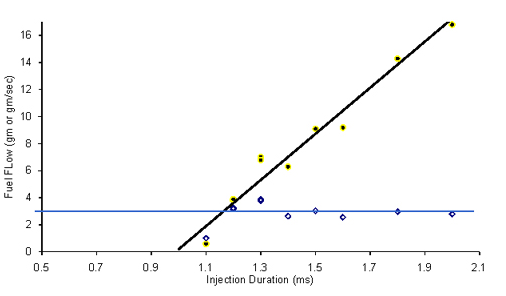

To determine the injector opening time the injector should be actuated several times at a consistent injection duration. For example, operate the injector at 1.5 milliseconds one thousand times. This can be done by connecting it to the controller, and “faking” the speed signal to get it to inject. Set the controller to deliver the desired injection duration, and run it form long enough (ie. a thousand cycles) to get significant fuel accumulation. Alternatively the timing signal can come from the running engine, but obviously not while running on the injector to be measured! When the injection duration is below the injector opening time you will not measure any significant amount of fuel delivered. Also the injector will make very little noise. As the injection duration is increased the noise will increase and the flow rate will eventually become significant. You can take the injector opening time to be the minimum injection duration that consistently delivers a measurable amount of fuel. Alternatively you can measure the delivered amount of fuel carefully and calculate back how much was delivered per injection. Plotting this up as a function of injection duration you will get a graph like the following from a Nippon Denso automotive injector operating at 3.5 bar. From this graph we can see that there is a linear trend in fuel delivered (black dots) as a function of injection duration. The slope of this line is the injector flow rate (diamonds), which is approximately 3 gm/sec. Where this line intersects with the horizontal axis is the injector opening time. This injector has an opening time of about 1.0 ms.