Load Cell Testing & Trouble Shooting

Load Cell Test

The load cell and amplifier can easily be tested together by obversing the voltage (amplifier output which should be fed into torque input terminals on the back of the controller) while changing the load on the load cell. Unloaded the amplifier should have a small DC voltage (the zero voltage). As load is applied this voltage should increase linearly proportional to the applied load. If the voltage decreases when applying load in nominal loading direction, reverse the Sig+and Sig - lines on the amplifier; this will cause the voltage to increase with applied load. When the load is removed the voltage should decrease back to the initial "zero voltage". If the assembly does not behave as indicated, it is likely that there is a problem with the load cell wiring and you should proceed to the following "Load Cell Trouble Shooting" section.

Load Cell Trouble Shooting

The amplifier in the unit is designed to wrok with standard wheatstone bridge configuration 4-wire load cells with resistance between 100 to 450 ohms. The excitation voltage (excite + relative to excite -) is either 5 or 10v depending on the voltage selector switch on the back of the amplifier. When functional Sig + and Sig - lines should both be at approximately 1/2 the excitation voltage. Connecting a voltmeter (set to the DC mV scale) between Sig + and Sig - you should see a very small voltage (a few mV) which change linearly with load. If the excitation voltage is properly applied and you do not get a repeatable and linear change in the Sig + and Sig - voltage, it is likely that your load cell either improperly hooked up, one of the leads is broken or the load cell itselfis damaged.

The most commom problems associated with the strain gages are:-

- Disconnected Leads - ones of the wires is not properly connected

- Short Leads - One or more of the leads is shorted together or to shield ground

- Internal Conneting Breakage - Ones of the wire bonds to the actual strain element is broken.

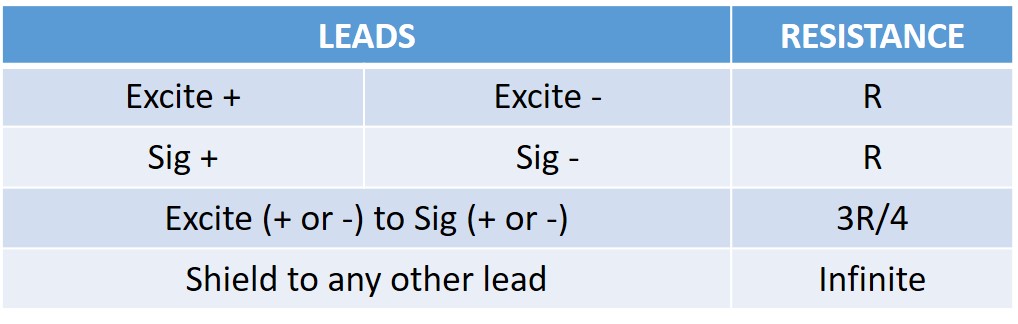

Any one of these faults may lead to the signal drifft, noise, no signal or signal pegged high or low. If your systems is exhibiting these faults, you should check the resistance of between the leads and compare them to the table below.

Download :Profile