How To choose the right Dyno?

Dynamometers are tools for measuring mechanical power, speed and torque, and provide a controllable load to the device being tested. Specifying a dynamometer based test system can be a confusing job initially. Often the requirements are not completely defined eg. “Measure the start up performance of a jet engine starter motor”. This could mean measuring just the stall torque (which is a function of rotor position with respect to the stator), or it might mean measuring the typical torque available to spool up the turbine, or even how long it takes to spool up the turbine. It is important to completely define the expected output of the dynamometer system, and even what testing is to be performed. For the example of the turbine engine starter motor we might want to have the dynamometer load the motor with 150% overload to simulate engine starting under cold conditions, or perhaps evaluate motor performance with lower current then the nominal rating.

Once the actual testing conditions have been fully defined, then the search for a dynamometer test system begins. There are a lot of different kinds of dynamometers, each with its own advantages and disadvantages in terms of speed, torque, power, cost, ease of installation, portability, power requirements, cooling requirements, thermal stability, and etc. Most commercial dynamometers systems are intended to measure the shaft power of an engine or motor, or the power output from a wheeled vehicle. There are a wide range of “special” dynamometers for measuring things such as the power, torque and thrust of an aero engine, or the torque and efficiency of wind turbine. If you need a special dynamometer it is best to review the information here to get an idea of the range of available units, and then contact us directly to help design a system for you. However, if you need a typical engine or chassis dynamometer, then please read on.

STEP 1 : ENGINE / MOTOR vs VEHICLE TESTING

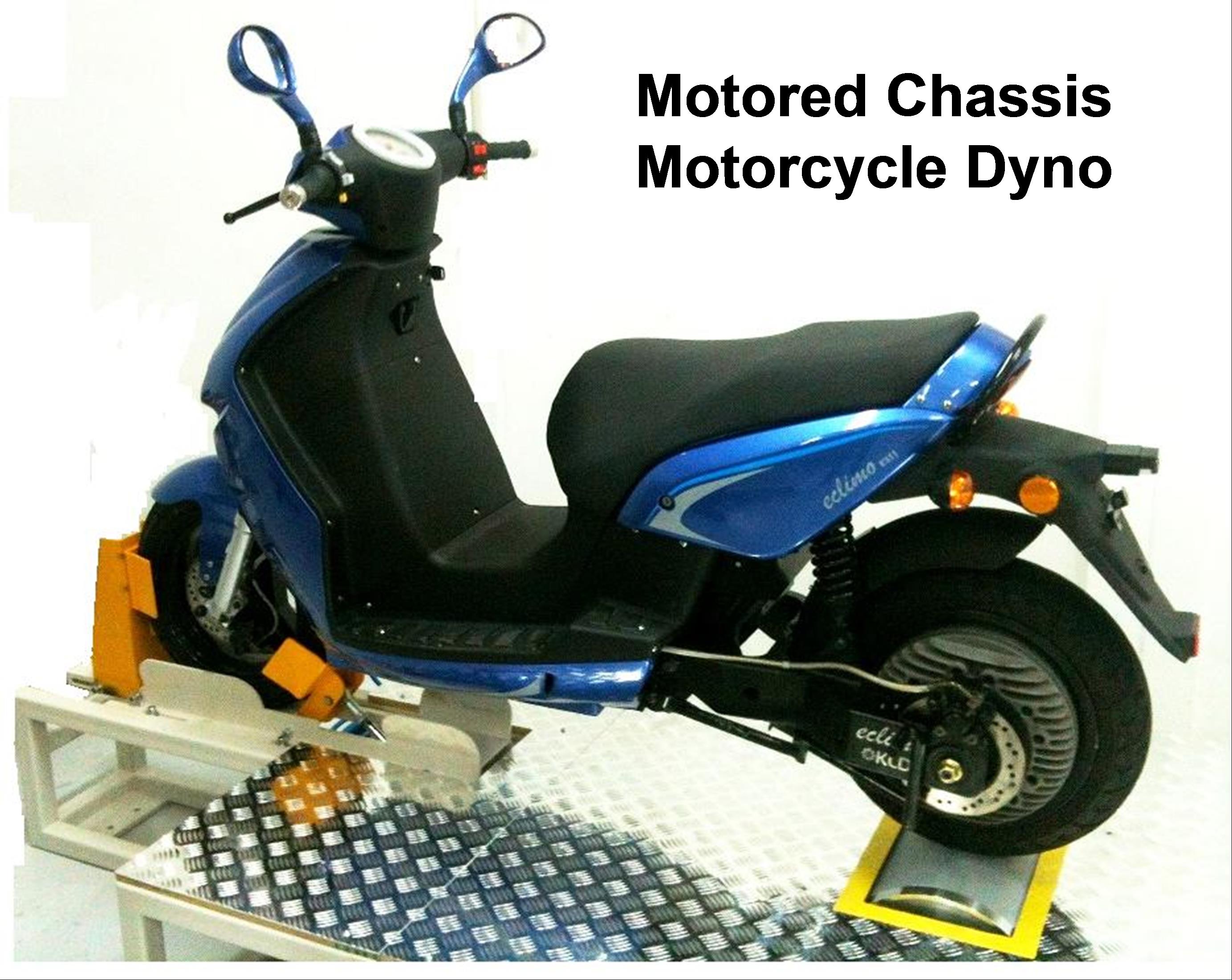

The first thing to decide is whether you need to test at the engine or motor level, or are you going to be testing at the vehicle level. Dynamometers can be coupled directly to the driven shaft of a motor or engine, or the dynamometer can be connected to a roller which is driven by the vehicle’s wheels. If the intention is to perform R&D on some aspect of engine performance (eg. The emissions and power effects of different biofuel blends on a research engine) where a single engine is to be tested over a long term (months), then an Engine Dynamometer is probably the right tool. For a factory setting where electric motors are to be tested for starting torque, or maximum power, then some kind of easily coupled Motor Dynamometer is required. If, on the other hand, you wish to test different vehicles often, and would prefer not to remove the engine or motor, then Chassis Dynamometer testing is what you need. Engine R&D can also be done on a chassis dynamometer, and you could perform “fleet” engine testing on an engine dynamometer (for example if you have a fleet of boats and need to qualify the engines before placing them back in service after maintenance), but in typical automotive applications chassis dynamometers are for testing large numbers of vehicles quickly, and engine dynamometers are for more in-depth work on a few engines for a longer duration.

STEP 2 : DYNAMOMETER SIZING

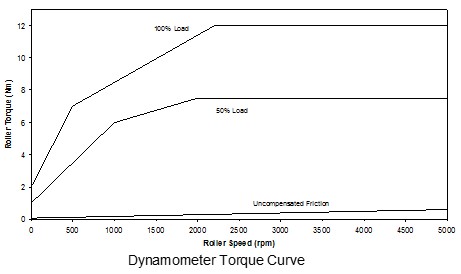

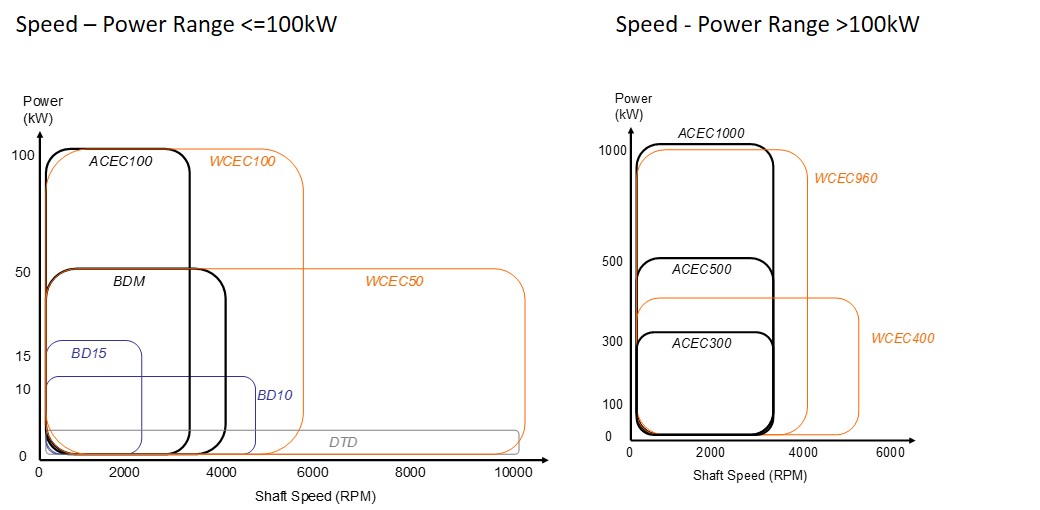

The crucial parameters for any dynamometer system are the maximum speed, torque and power. These parameters are not completely independent: power is the product of speed times torque. Different types of dynamometers will have different advantages in terms of maximum speed, maximum torque at lower speeds, and even torque versus temperature of the device. Most dynamometers won’t give full torque at low speeds, instead they require motion of the rotor in order to generate torque. Additionally Air Cooled dynamometers are generally less expensive than Water Cooled dynos because they don’t require water passages, pumps and seals. The Air Cooled dynos, however, tend to get hot when running high torques, which can degrade their torque performance. Once they cool back down again they generate high torque normally.

Generator type dynamometers are relatively inexpensive and convenient for lower power ratings, and don’t tend to heat up as the power is dissipated as heat in an electrical “dump load”, rather than in the dynamometer. Also there is a tendency to oversize dynamometers when ordering. The thinking is that in the future you may want to test higher capacity engines or vehicles, so it is better to buy a bigger system now. This may be a good idea, but you also need to consider that by over sizing the dynamometer, it may reduce the maximum speed (larger dynos tend to have lower speed limits due to material strength constraints). Be sure that by over sizing you aren’t limiting your other specifications unnecessarily. A partial list of our dynamometers is given below. Please check with us if you need something that isn’t shown.

CHASSIS DYNAMOMETERS

| MODEL | DESCRIPTION | MAX POWER (KW) |

|---|---|---|

| HCD 5 | Hypermileage Chassis Dynamometer | 5 |

| HCD 10 | Hypermileage Chassis Dynamometer | 10 |

| CCD 10 | Compact Chassis Dynamometer | 10 |

| CMD 50 | Compact Motorcycle Dynamometer | 50 |

| SCD 50 | Superbike Chassis Dynamometer | 50 |

| SCD 100 | Superbike Chassis Dynamometer | 100 |

| SCD 200 | Superbike Chassis Dynamometer | 200 |

| SCD 300 | Superbike Chassis Dynamometer | 300 |

| ACD 100 | Automotive Chassis Dynamometer | 100 |

| ACD 300 | Automotive Chassis Dynamometer | 300 |

| ACD 1000 | Automotive Chassis Dynamometer | 1000 |

ENGINE DYNAMOMETERS

| MODEL | DESCRIPTION | TYPE | MAX POWER (KW) | MAXRPM |

|---|---|---|---|---|

| DTD | Desk-Top Dynamometer | ACEC | 2 | 10,000 |

| BD10 | Bench-Top Dynamometer | GEN | 10 | 4,500 |

| BD15 | Bench-Top Dynamometer | GEN | 15 | 2,400 |

| BDM | Medium Bench-Top Dynamometer | ACEC | 50 | 4,000 |

| BDW50 | Bench-Top Dynamometer | WCEC | 50 | 10,000 |

| BDA100 | Bench-Top Dynamometer | ACEC | 100 | 3,000 |

| BDW100 | Bench-Top Dynamometer | WCEC | 100 | 5,500 |

| EDA300 | Engine Dynamometer | ACEC | 300 | 3,000 |

| EDA400 | Engine Dynamometer | WCEC | 400 | 5,000 |

| EDA500 | Engine Dynamometer | ACEC | 500 | 3,000 |

| EDA960 | Engine Dynamometer | WCEC | 960 | 4,000 |

| EDA1000 | Engine Dynamometer | ACEC | 1000 | 3,000 |

NOTES: AC = Air Cooled, EC = Eddy Current, WC = Water Cooled, Gen = Generator

STEP 3 : OPTIONAL EQUIPMENT

A wide range of optional equipment is available for both chassis and engine/motor dynamometers. Fuel scales are used to accurately measure fuel consumption, emissions analyzers measure smoke, HC, CO, CO2, NOx, O2 and other exhaust gases, and clamp meters can be used to measure currents and voltages. Many of the following sensors can be directly integrated into our standard Dynamometer Controller via the existing DAQ channels for display and analysis. We can supply any of the required equipment listed below.

| Combustion Analysis | Measures pressure in the combustion chamber to determine Pressure – Volume curve, Indicated Efficiency, and analyze various Combustion parameters such as knock, stability and flame speed. |

| Exhaust Gas Analyzer | Measures Smoke (for Diesels), Particulate Matter, Hydrocarbons, Carbon Monoxide, Carbon Dioxide, Nitrous Oxides, and etc. from Engine or Vehicle Exhaust |

| Air / Fuel Ratio Sensor | Also known as a “Wide Band Oxygen” sensor, this allows direct Measurement of the air/fuel ratio crucial for proper tuning. |

| Digital Fuel Scale | Used to measure Instantaneous fuel flow |

| Current Clamp Meter | Measures Currents to electric motors and from generators/batteries. |

| High Voltage Probe | Measures Currents to electric motors and from generators/batteries. |

ADDITIONAL SENSORS:

- Engine Temperature

- Exhaust Gas Temperature

- Intake / Exhaust Manifold Pressure

- Air Flow

- Knock Sensor